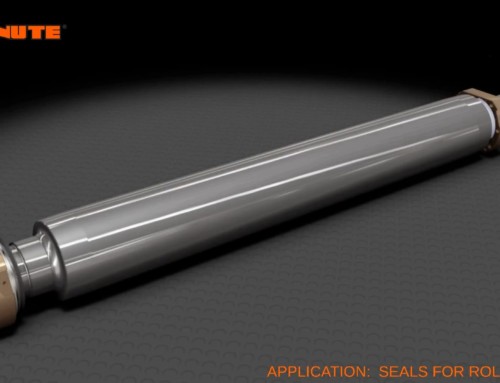

Thrusters are propellers used on vessels to position them in harbours. In these systems different sealing rings are installed.

A typical application is the vertical main shaft, where there are two seals, one of which is kept as a spare seal with no lip contact to the shaft due to a recess. This can be pushed into position in case of need. The maximum Rpm is 750 at a max. pressure of 0.2 bar.

The expected seal life-time is about 1 year.

An important thruster manufacturer in northern Europe used to encounter continuous leakage problems by using a textile/rubber seal, able to withstand approximately 6 bar pressure and made of FKM, therefore quite expensive.

The seals used were not giving the proper performance due to the fact that axial clamping was not enough, and also the venting system did allow pressure peaks.

It also appeared that the grease supplied from the top via the spare seal was not sufficient, leaving the main seal without lubricant.

TENUTE proposal to solve the customer problem was TR/5-ML–MA-PTV® in NBR, a self retaining and pressure capable seal that does not need end covers. In addition, PTV technology gives outstanding performances, compared to ordinary seals.

During the study phase, TENUTE R&D Dept also suggested an alternative solution to what the customer considered at the beginning.

Thanks to TR/5-ML–MA-PTV® features, it could be possible to design a double seal assembly arrangement.

This arrangement allows the primary seal to work normally, while the secondary is mounted in a subordinate position and free, ready to be put into service in case of break down or usual maintenance.

As far as materials are concerned, NBR compound was selected, combined with PTV technology, as an alternative to FKM used until then.

TENUTE patented system PCT/EP/2006/004962 enables to combine wear resistance and a very low friction coefficient, typical of PTFE, to resilience and reactivity of elastomers.

In this application, a customized formula for marine industry was studied: a NBR elastomer that should feature a very high resistance to atmospheric agents, oils and low temperature with brittleness point at -40°C. Furthermore, PTV technology prevents from “stick-slip” effects, which is typical of sealing rings with non-continuous movement.

TENUTE TR/5-ML-MA-PTV® made the leakage problems stop.

The cheaper price (NBR vs FKM) had an effect on the customer’s purchasers, even though designers had already made the decision of changing the seal.

In addition, the technical support provided by TENUTE was a key factor in the change.

For more information, please visit Tenutesrl.com

Leave A Comment