NSM – Nuova Saccardo Motori is a company of Amer group, producing DC motors with permanent magnets for different industrial sectors.

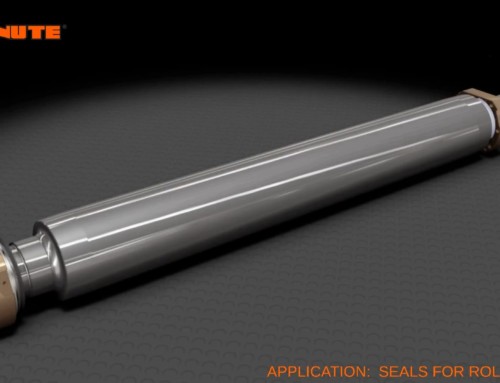

In 2015 NSM began to work with Tenute on a project of sealing system for motors used on generators in micro-wind sector, to be installed at two sites, in India and in North Africa. These motors were used in small-size generators called PMG 295 T, installed outside homes or offices; capable to deliver a maximum rated power of 6kVA at 150rpm.

Both sites showed critical atmospheric conditions, such as permanent presence of wind, sand and dust;

The mechanical labyrinth existing in the generator was not suitable to ensure an optimal sealing. The required solution was a seal that would act as a barrier to prevent the presence of external impurities inside the mechanical parts.

Tenute Technical Office suggested a solution that should be integrated into the existing labyrinth, taking into account the limited space available.

A sliding seal was therefore proposed: TENUTE model TR/VL-ML-PTV in NBR, granting to the user multiple advantages.

The main benefit of TR/VL-ML-PTV is an excellent sealing performance against dust and other contaminants, keeping friction power losses to a minimum level. In addition, PTV coating enables the seal to work without lubrication.

During 2017 tests were carried out for 10,000 hours continuously (with periodic shutdowns for measurements) to check seal temperature and wear.

After about 9,000 working hours, an almost constant temperature of around 45° C was detected.

In September 2018, NSM provided a complete report with photo taken with an IR thermal camera in which it was possible to check seal temperature while working with its lip in contact with the generator metal labyrinth.

Testing time: 16,884 hours!!

After 16,884 hours of operation, the seal was disassembled, without having found functional anomalies. The temperature measured with thermograph camera on the flange, has reached a maximum value of 52° C. Inside the wind generator there were no presence of dust, water or oxidation traces.

The test ends with a POSITIVE RESULT.

Thanks to positive results, after one year tests, the customer decided to accept and validate the seal proposed by Tenute, also related to the dynamic aspects of the application.

Leave A Comment