Great attention to product control has always been paid by TENUTE, which over the years has invested many resources in this strategic field.

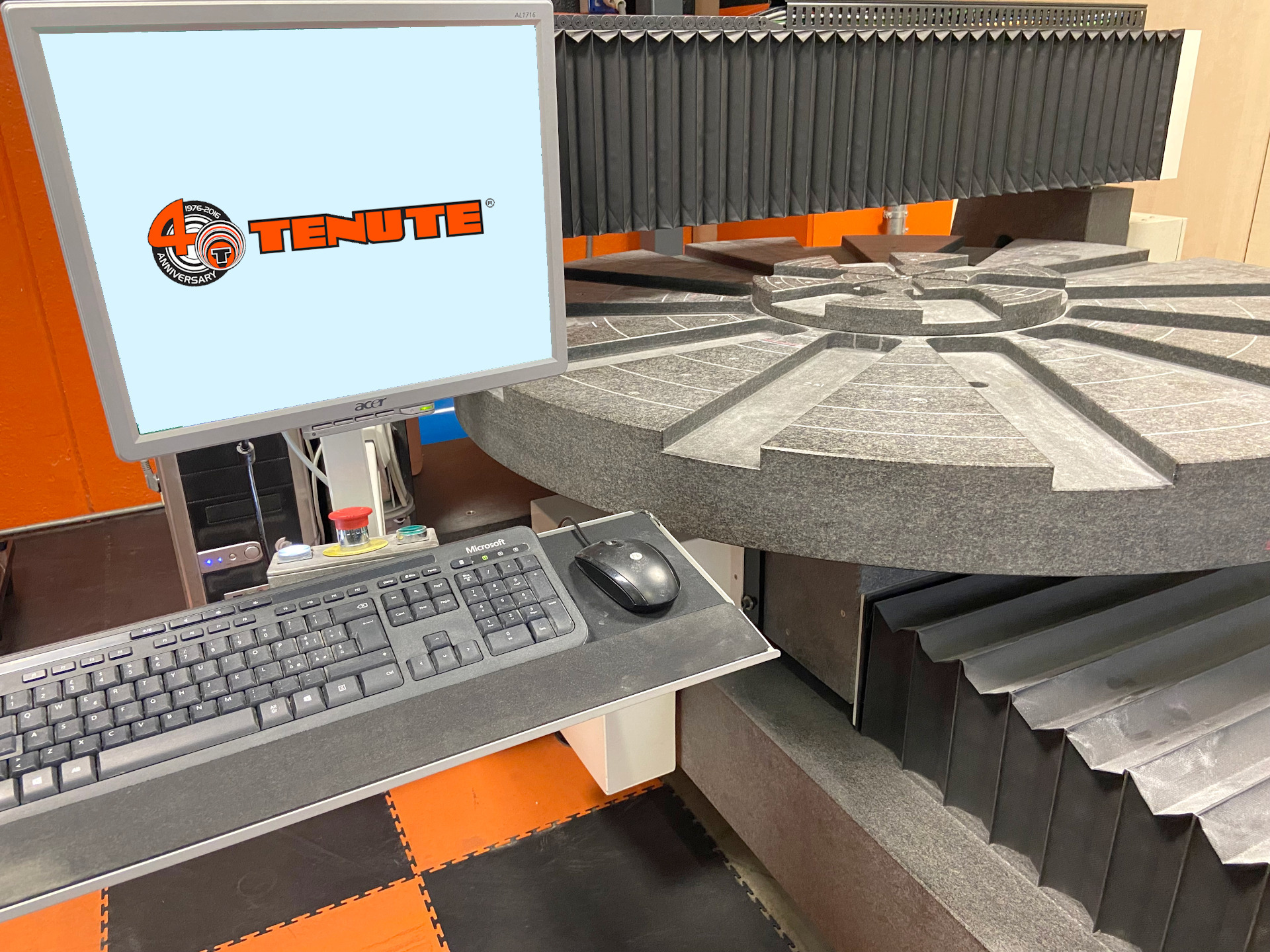

A highly innovative equipment to perform an extremely accurate dimensional control of seals has been developed and set up by TENUTE together with Metrology Faculty of Turin Polytechnic University, that certified the machine, named Polaris.

Polaris machine is able to measure 360 points on seals up to diam. 1500mm, issuing a graphic and data report.

Its astonishingly non-touching technology prevents seals from being deformed during all control and measurement phases, granting to TENUTE customers the delivery of visually and dimensionally perfect pieces.